Heat Recovery Steam Generator

BHI makes an effort for customer satisfaction and efficiency of product innovation.

Overview

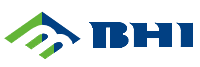

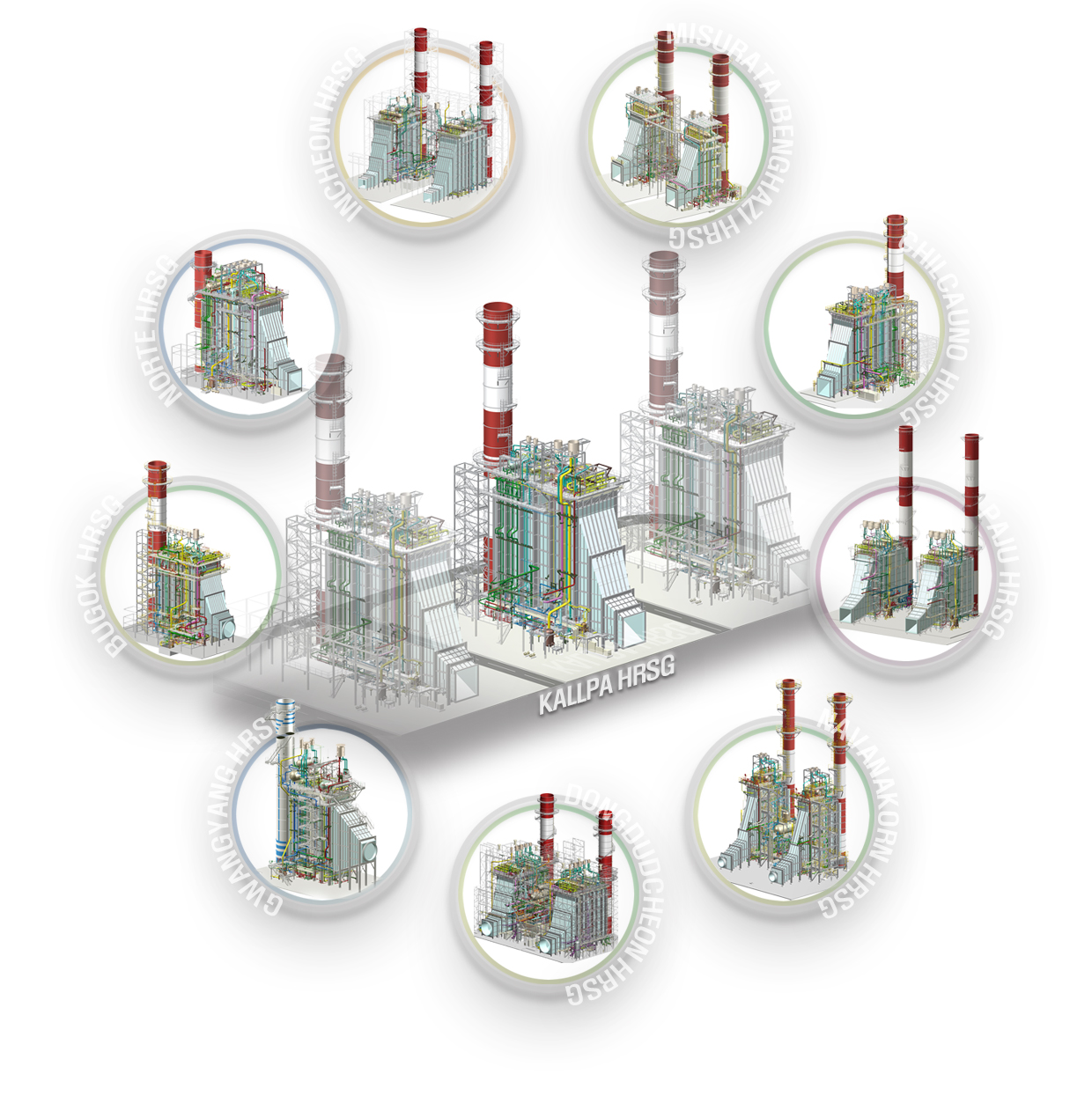

HRSG technology is essential for combined cycle efficiency. Through the acquisition of HRSG technology from Wood(formerly Amec Foster Wheeler), BHI HRSG‘s rich history extends back to 1958, when our first HRSG was supplied to Rio Pecos CCPP in Texas, USA.BHI’s HRSG integrates experience, technology and expertise for its perfection. With more than 500 HRSGs installed in 42 countries, BHI‘s HRSG technology is acknowledged for its customized design and manufacturing services, which are also reliable and cost-effective. We offer horizontal and vertical type HRSGs for gas turbine size from 10MW up to the largest and the most advanced.

Major Design Features

Enhanced Total Engineering Services

Thermal Engineering

Proper equipment sizing, verification of thermal load and life time

analysis and life cycle analysis, gas path flow distribution analysis,

and general thermal-mechanical engineering.

Mechanical Design

Robust internal hanger support configuration and static/ dynamic

load analysis for steel structure and piping.

Fabrication and Quality Control

Established zero-defect fabrication and quality

control procedures by implementing once- through

production line, from finning to hydro test,

at BHI’s world-class Moro shop.

Field Technical Advisor and A/S

Utilize experienced manpower by

dispatching technical advisor during

erection and commissioning processes.

Current status

Acquisition of HRSG Technology

BHI started its HRSG business as a licensee of Wood(Formerly Amec Foster Wheeler) in 2005 and has been a leading HRSG supplier around the world.

In 2020, BHI acquired HRSG technology from Wood and became incomparable self-reliant HRSG technology owner in Korea.

BHI provides state of the art, innovative HRSG engineering to clients all around the world with the ownership of HRSG technology.

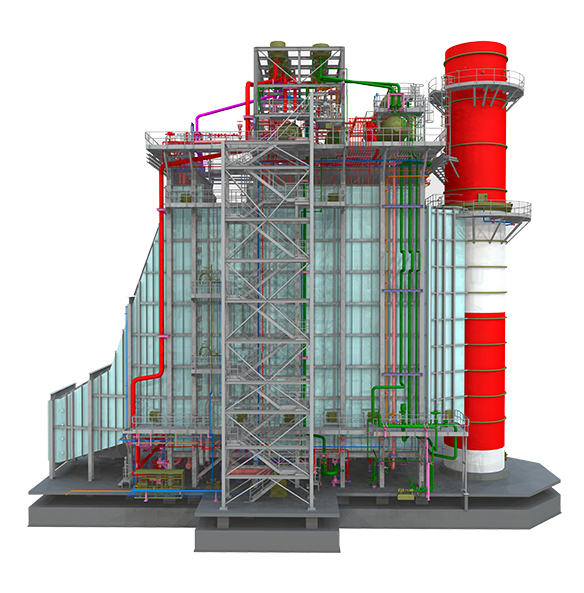

Harp Assembly / Module / C-Frame(Section) / O-Section

Major Projects Reference

Qurayyah Independent Power Plant

(333MW x 12, Saudi Arabia, SAMSUNG C&T, 2013,

GT: SGT6-5000F)

GT: SGT6-5000F)

York ll CCPP

(400MW x 2, Pennsylvania, USA, Calpine, 2014,

GT: GE 7FA.05)

GT: GE 7FA.05)

Anyang

(472MW x 2, South Korea, GE, 2017,

GT: GE7HA.02)

GT: GE7HA.02)

Fujairah lll IPP

(750MW x 3, UAE, Samsung C&T, 2020,

GT: M701JAC)

GT: M701JAC)

Pocheon LNG Power Plant

(1600MW, South Korea, Daelim, 2013,

GT: M501G)

GT: M501G)

Black Point D2

(650MW, Hongkong, SIEMENS Energy, 2021,

GT: SGT5-8000H)

GT: SGT5-8000H)

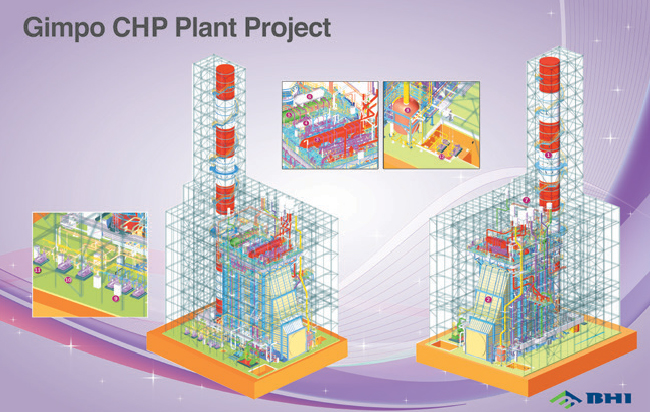

Gimpo CHP Plant

(495MW, South Korea, Doosan, 2021,

GT: DGT6-300H S1 & S2)

GT: DGT6-300H S1 & S2)

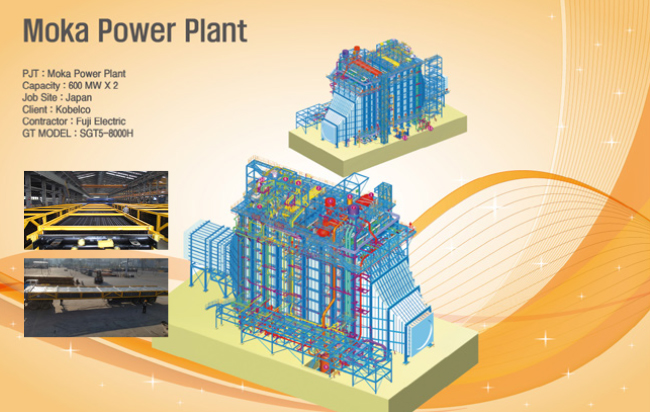

Moka Power Plant(MPP)

(600MW x 2, Japan, Fuji Electric, 2014,

GT: SGT5-8000H)

GT: SGT5-8000H)

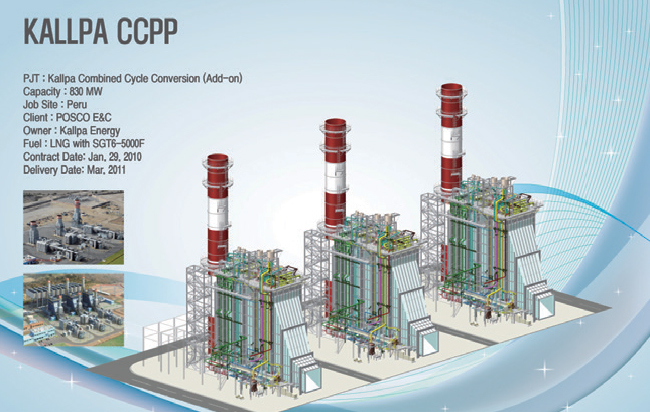

Kallpa Combined Cycle Conversation

(830MW, Peru, POSCO E&C, 2011,

GT: SGT6-5000F)

GT: SGT6-5000F)